In the 1970s, The Six Million Dollar Man, a television series, brought oohs, ahhs and chuckles into people’s home, as it combined science fiction with wild adventure. Almost five decades later, 3D printers are bringing bone replacements into operating theaters and disruptive new medical technology is redefining the effectiveness of prosthetic devices.

Discover how today, the bionic body is perhaps closer to reality than fiction.

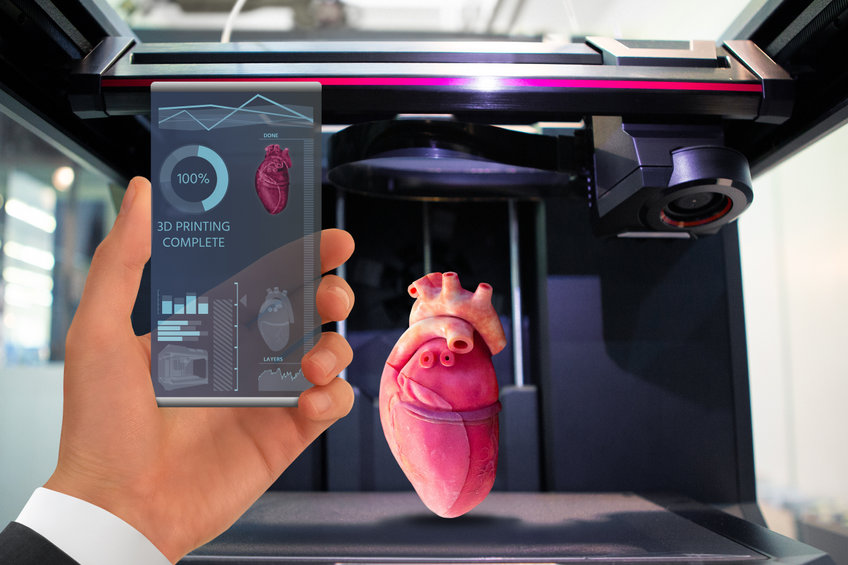

Printing Up a New Liver

According to CNBC, entire organs, ready for transplant, will be available within 10 years. Bioprinting, which involves combining human stem cells with water and biocompatible material, can produce tissue that is living and capable of becoming actual body parts like skin, a kidney, bone cartilage or a liver.

Special types of 3D printers today produce human tissue. This same technology can also produce customized prescription drugs, allowing for individualized medicine for each patient.

Bionic Hands & Disruptive Technology

Other new advances are drastically changing the way human being deal with medical problems. These advances are radically different from previous treatments.

For example, much more efficient bionic hands and feet are becoming commonplace in today’s medicine. Current bionic hands allow each finger to move independently, controlled by tiny separate motors. Electrodes attached to a person’s forearm send signals to open and close the hand. Better than the original, it can turn full 360 degrees at the wrist.

New bionics use cutting-edge software, durable batteries and highly effective microprocessors. There is even an implant that helps quadriplegics control their limbs through the use of wiring direct to their brains. Researchers in London working on a project called appropriately Bionic Man, concluded that more than 50% of the human body could be rebuilt through technology.

The Future of Medical Devices

In the past, engineers in labs created medical devices. They primarily worked to please patients, doctors, hospital buyers, government oversight inspectors and the people paying the bills.

This is transitioning to a more practical model. Researchers and inventors are working directly with patients and physicians to create new devices that meet specific needs. These fit medical requirements more precisely, justifying their cost.

With the introduction of the 3D printer, surgeons manufacture more precise prosthetic devices and implants. These prosthetics exactly fit the dimensions of each patient. This exact-fit technology is more cost-efficient and enables easier recoveries.

For example a surgeon today has the ability to implant a new kneecap, specifically printed to the exact size of the patient. In an interview with Autodesk’s Redshift Magazine, Katy George, McKinsey’s expert in its operations practice and pharmaceutical and medical products, spoke about technology’s impact on the medical device industry’s future:

“Imagine a 3D-printed knee, which is exactly fit to somebody’s size that was just delivered, maybe even printed out at a regional lab, and is delivered immediately into the surgery. So you have better outcomes, you have a better product, and you have a completely different supply chain, and maybe a different business model even as to what the role of a manufacturer is versus the role of a distributor, versus the role of the hospital.”

The new world of bionics and 3D printing technology is changing the world. Engineers, physicians, patients and industry deal with transplants, implants and prosthetic devices in a different way than before. The bionic body of the future is here.